Permanent fieldbus monitoring enhances availability

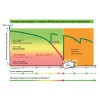

Continuous production can only be ensured and out of the blue failures avoided if beside the individual components the bus is considered a wear part and its status known.

In many a case the regular maintenance of the field bus would make sense. But this is not easy to achieve because the number of maintenance staff is decreased for economic reasons. So, the „INspector“ of Indu-Sol comes in as the ideal partner. It is integrated in the respective network on a permanent basis and monitors constantly the logical data traffic. As a first step Indu-Sol offers inspectors for PROFIBUS, PROFInet, CAN bus and ASinets as well as analyzers for Industrial Ethernet.

A central software informs the plant operator both on the current and historical network status. As soon as the communication has exceeded or fallen short of certain quality parameters, the maintenance personnel gets a warning. It is done by a visual display in the software and transfer to the process control system via OPC or SNMP, email or switching of an alarm contact. Thus, it is possible to eliminate causes of fault before a trouble arises and becomes apparent by a plant shutdown.

See also

- VIPA SLIO – Podsumowanie nowych rozwiązań systemu 29/09/2014

- VIPA SLIO CPU – Procesor dla systemu SLIO 09/06/2014

- 315SN/PN ECO – Teraz PROFINET w tańszej odmianie 10/07/2013

- PROFIBUS Repeaters from VIPA 30/11/2011

- VIPA SPEED7 CPU 317 PN 02/07/2011

Gallery

Useful links

Please find below a list of bookmarks related to the topic of this page. Some of these may lead to external sites.